45 drilling thru stainless steel

How to Drill Into a Stainless Steel Sink - Lifehacker Step Three: Start Drilling. Attach a ¼" carbide tipped bit and start drilling. Don't run your drill at full speed; instead, go half or a third the max speed. This will keep it from overheating ... How Do You Drill A Hole In A Stainless Steel Tube? [Drill Like A Pro] Keep cutting the edges of the drill bits by holding it horizontally. Grind the drill bits in all the corners to sharpen the edges and check if the edges are equal in length and angles. If you think a touch up is needed, repeat the process slowly and give some time to cool off the drill bits to use it again.

How To Drill Through Hardened Stainless Steel: 71 Shocking Facts This time, we're going to talk about How To Drill Through Hardened Stainless Steel. There is a lot of information about How To Drill Work Hardened Stainless Steel on the internet, of course. Social media are getting better and better quickly, which makes it easier for us to learn new things. Rpm For Drilling Hardened Steel and How to drill Stainless Steel? are also linked to information ...

Drilling thru stainless steel

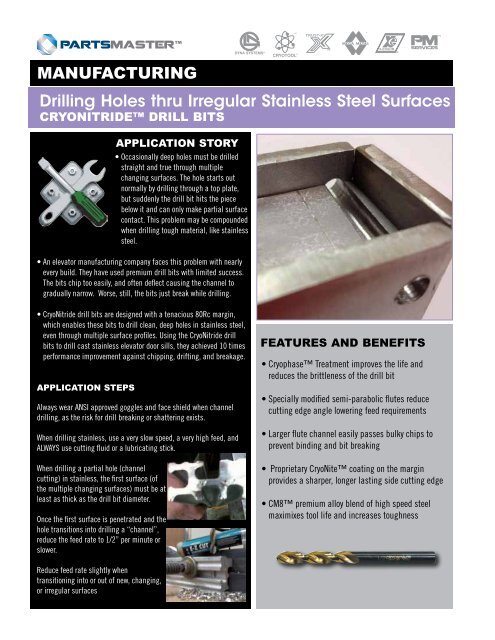

Drill Bits for Stainless Steel (Which One to Choose) Uses and Functions Stainless steel is a hard metal, unlike aluminum, iron, and copper. 118 and 135 degree-bits are most appropriate. They are of high precision and their cutting points bite into metal without slipping. Besides, new drill bits in this class cut well into metal than any other bits. Split point bits and twist drill bits are great for working on steel. Machining Metals: 6 Tips for Drilling Stainless Steel The senior manager of global product engineering at Kennametal says productive hole drilling starts with the correct tool. Tip No. 1: Go for Solid Carbide Drills "Stainless steels generate a lot of heat, and solid carbide drills are not only more heat-resistant than high-speed steel [HSS] and cobalt but are also harder and stronger," George says. How to Drill Steel: 15 Steps (with Pictures) - wikiHow Make sure you hold your drill straight so you don't make a crooked hole in the steel. [6] 3 Drill slowly and apply firm downward pressure. Use a low RPM setting and keep a steady pressure as you push the bit through the metal. Start and stop drilling often to give the steel a chance to cool down and lubricate the area.

Drilling thru stainless steel. Drilling stainless steel - 5 easy steps - Cobalt drill bits Step 1. Drill bit When drilling into stainless steel the choice of drill bit will ultimately determine how successful you will be. Cobalt drill bits are considered the best option due to their ability to withstand the high temperatures created when drilling harder metals. Step 2. Speed Guide To Drilling & Tapping Stainless Steel | Regal Cutting Tools The best HSS drills for stainless steel are alloyed with tungsten or molybdenum. Carbide tools can be used on long runs without the need for frequent tool changes, making them ideal drills and taps for stainless steel. Coatings - Coating drills in titanium nitride makes them more resistant to heat. Know How: Drilling Stainless Steel - Sail Magazine Here is the right way to drill stainless steel: Start with a sharp drill and have it turning as slowly as your drill or drill press will allow. I set my drill press to its slowest speed or run my portable drill as slow as the trigger will allow. You need to exert a lot of pressure on the drill bit—as much as it will bear. How to Drill Stainless Steel? - A1 Custom Drilling stainless steel during installation or renovations In the first place, you must be sure of where to drill the hole. Use a marker pen to spot the particular area. Now, consider the thickness of the hole that you are going to drill. In case it is less than 3 mm., you can drill the hole using a single bit.

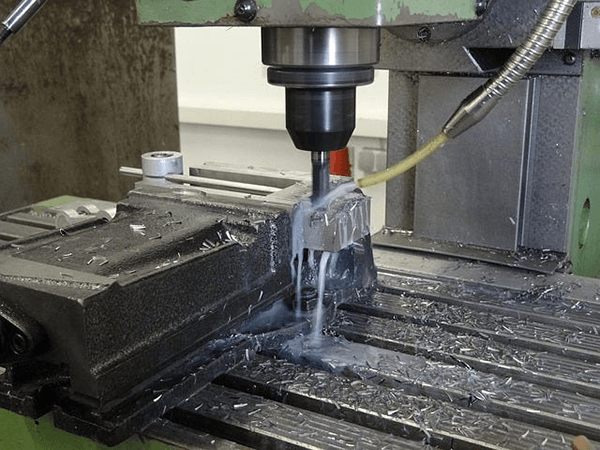

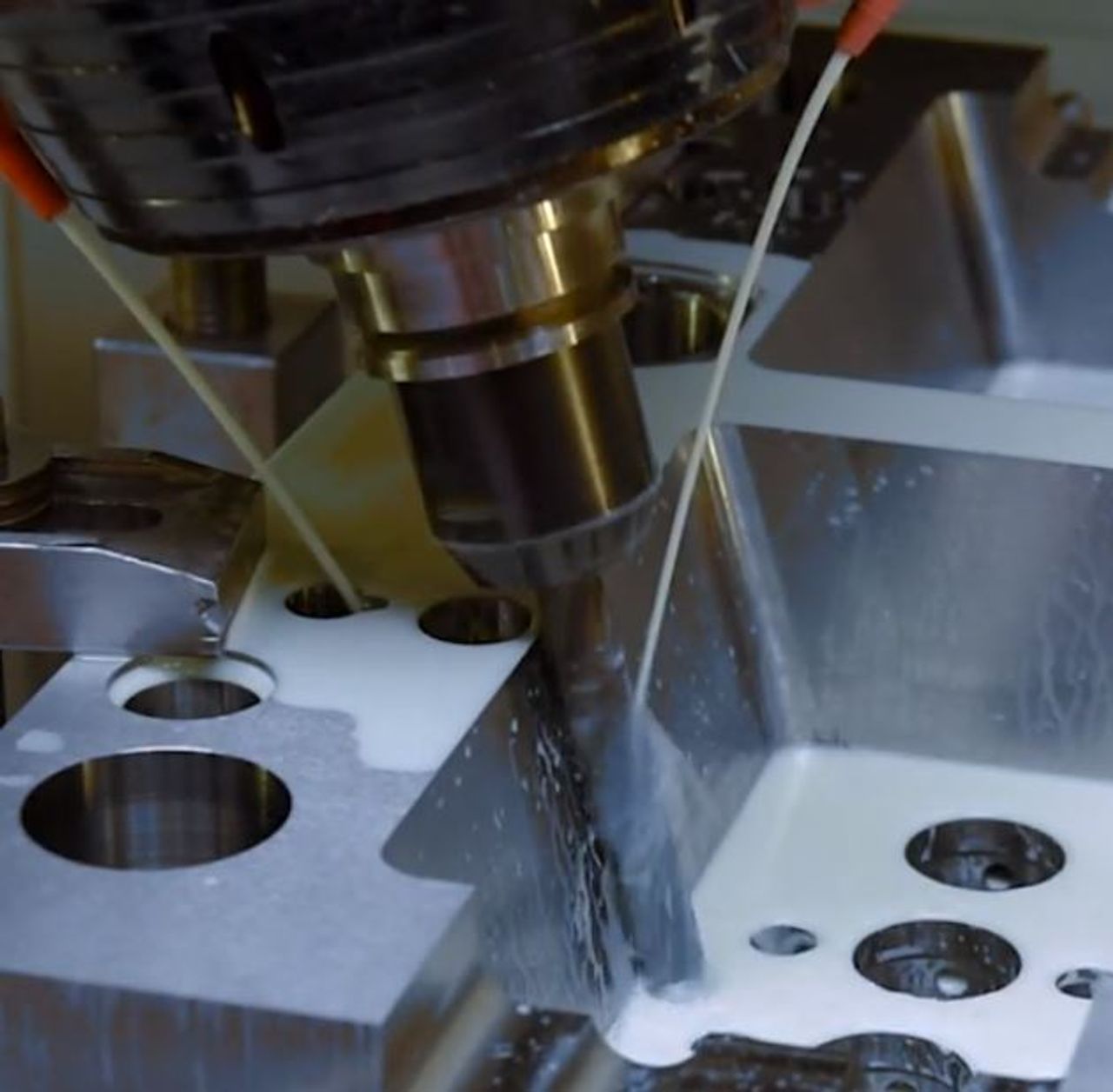

How to Drill Through Stainless Steel - AutoDrill Drilling through stainless steel is much like drilling through any other type of metal but with a few key differences. Using high-speed drill bits or better is mandatory. There are also other steps to drilling this material that will make the process easier. Many people have drilled holes into plain old steel with satisfactory results. Why is Stainless Steel so Hard to Drill? - workshoppist.com Drilling stainless steel leads to high cutting temperatures already at moderate cutting speeds, as indicated here by oil smoke. How high the temperature near the drill bit cutting edges actually rises will depend on many factors, such as speeds, feeds, cutting angles, whether coolant or lubricant is used, and so on. Handbook: How to drill stainless steel step by step - wordpress 1 Step By Step Guide On How to Drill Stainless Steel 1.1 Step 1: Safety First 1.2 Step 2: Find the Right Surface 1.3 Step 3: Secure the Stainless Steel in Position 1.4 Step 4: Mark the Spot 1.5 Step 5: Start Drilling 1.6 Hand drilling stainless steel 1.7 Using a power drill to drill stainless steel 1.8 Step 6: Clean Up How to drill Stainless steel - Ideas & Advice | metals4U When drilling stainless steel, one of the best indicators of whether the speed, pressure and feed rates are correct is to watch the swarf; the swarf should cleanly exit the hole and be helical in shape and short in length. Stainless swarf should resemble the original colour of the stock metal or have a yellow tinge to it.

How to Drill through Hardened Steel | Machine Handyman Firstly place the hardened steel on a workbench and then secure it using clamps so it can move while drilling. If you don't firmly tighten the clamps, the steel will spin and can injure you. But if the working piece is heavier steel, you don't need to secure it. If You Hate Drilling Through Stainless Steel Try This the trick for drilling stainless is slow speed and a sharp bit. The way to tell your drilling too fast is that it will make a high squealing sound, very annoying. Also i have only had luck pre-drilling with step-bits, like others said, trying to drill the initial hole with a step-bit is a waste of time IrregularPulse Hobby Collector HBT Supporter How to Drill Stainless Steel | SawsHub Stainless steel can be penetrated by a handheld drill with a cobalt or high-speed steel bit. Care must be taken to avoid overheating. Accidental overheating can cause damage and discoloration of the metal. It increases the risk that the steel will 'work harden', becoming more difficult to drill through. Use lubrication or water to avoid this. How to drill stainless steel - YouTube How to drill stainless steel - YouTube Stainless steel can be difficult to drill. The trick is to not let the stainless get too hot or else it can work harden. In this video some 316...

How to Drill Holes in Stainless Steel - PassageMaker Drilling stainless steel can be a hot mess. Here's a quick tip for keeping your cool. CAPT. BILL PIKE Jul 21, 2020 It's All About H2O Some people will tell you that drilling crisp, accurate holes in the harder grades of stainless steel is pretty darn problematic if not impossible.

How to Drill through Stainless Steel-Ideas and Advice This technique keeps the drill bit in place. A misconception is that you need expensive and higher grade drill bits to do the job for stainless steel but no, your standard HSS drill bit should be more than enough. Step Two Lubricate! Utilize a cutting fluid or multipurpose oil tolubricateyour drill bit and reduce friction as well as heat buildup.

How to Drill through Metal - Techniques and Tricks How to Drill Through Different Types of Metal There are MANY different types of metal out there. Most of us typically use just a few: carbon steels like mild and stainless steels, aluminum, or alloys like brass or bronze. Machinists approach every metal differently and want to know the EXACT type of steel or alloy they are working with.

Drilling 17-4 ph stainless - The Home Shop Machinist & Machinist's ... 09-03-2003, 12:01 PM. 17-4 PH is both hard and tough and it tends to work harden like crazy. Here's where you need all the driller's tricks. Use a new drill if you can. Used drills frequently have worn margins near the drill point. 0.002" margin wear is fatal in some materials like hard bronze.

How to Drill Stainless Steel? - 07 Easy Steps Guide Place Stainless Steel Workpiece Properly Before you start drilling, secure the workpiece to a sturdy surface using clamps or a vice. Do not hold steel using one hand when drilling with the other. It will make the steel spin or slash with the pressure you add. Make sure to use at least two clamps to safely hold down the workpiece.

How to Drill Into Stainless Steel - Charles & Hudson Use pressure. You need to drill straight down and with force. Let the drill do the work. 6. Take breaks. You'll need to take a few breaks for the bit and stainless steel to cool down. Be patient. Stainless Steel actually hardens as it heats up so go slow. You should have a nice clean hole and use a file to smooth out the edges and wipe down ...

Best Drill Point For Stainless Steel Of 2022: Completed List Hymnorq 23/64 Inch Dia. x 4.88 Inch Long M35 Cobalt Steel Twist Jobber Drill Bits 5Pcs Pack, 135 Degree Split Point, Extremely Heat Resistant, for Stainless Steel and Cast Iron View on Amazon SCORE

Pro Tips: How to Drill Stainless Steel - Make It From Metal Drilling stainless steel needs to be done with sharp bits, low RPM, higher cutting pressure (feed), and lots of lube/coolant. High RPM will lead to immediate burned-out drill bits. Beyond that, there are a few other tips that can help you get the job done, like how to keep everything stable and how to choose the right bit. Realistic Drill Sizes

how to drill stainless steel - YouTube Drilling stainless steel is not as difficult as you may think and you don't need special drill bits like some will tell you. The trick to drilling stainless steel is in the speed of...

How to Drill Steel: 15 Steps (with Pictures) - wikiHow Make sure you hold your drill straight so you don't make a crooked hole in the steel. [6] 3 Drill slowly and apply firm downward pressure. Use a low RPM setting and keep a steady pressure as you push the bit through the metal. Start and stop drilling often to give the steel a chance to cool down and lubricate the area.

Machining Metals: 6 Tips for Drilling Stainless Steel The senior manager of global product engineering at Kennametal says productive hole drilling starts with the correct tool. Tip No. 1: Go for Solid Carbide Drills "Stainless steels generate a lot of heat, and solid carbide drills are not only more heat-resistant than high-speed steel [HSS] and cobalt but are also harder and stronger," George says.

Drill Bits for Stainless Steel (Which One to Choose) Uses and Functions Stainless steel is a hard metal, unlike aluminum, iron, and copper. 118 and 135 degree-bits are most appropriate. They are of high precision and their cutting points bite into metal without slipping. Besides, new drill bits in this class cut well into metal than any other bits. Split point bits and twist drill bits are great for working on steel.

.jpg?v=fcb74452)

0 Response to "45 drilling thru stainless steel"

Post a Comment